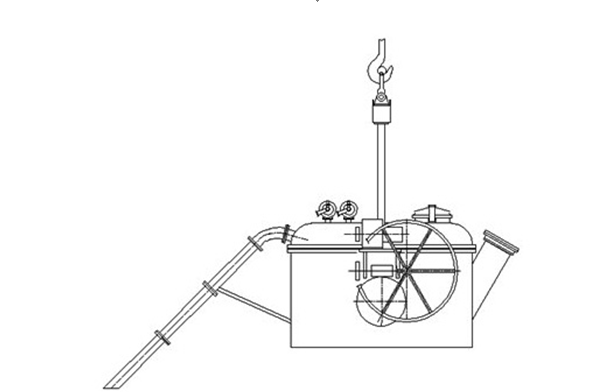

Vacuum Ladle for Aluminum Discharging

The vacuum ladle is special equipment for sucking molten aluminum out of an electrolysis bath and transporting it to the casting workshop, and is required to adapt to the working environment of the electrolysis workshop and the casting workshop.

Regional Conditions:

Maximum magnetic field: 150GS

Composition of vacuum ladle

The vacuum ladle is composed of a ladle body, a ladle cover, a transmission mechanism, an aluminum suction pipe, a manhole device, an aluminum flowing port, an injector, a ladle hanger and so on.

Working Principle

The vacuum ladle carries out vacuum negative-pressure aluminum discharging under the working pressure of 0.5-0.6Mpa and ≥60kPa, and the injector is a crucial key part essential to generation of vacuum in the ladle and is shown in the figure 2. Compressed air conveyed from an air compressor of a crown block or an air compression station of the electrolysis workshop enters a jet nozzle, high-pressure air quickly passes through a spherical sleeve, and negative pressure (namely vacuum state) is generated at the periphery of the spherical sleeve to form an injection effect, so air in the ladle is injected into a silencer sleeve together with the compressed air through a flared pipe under the action of atmospheric pressure and discharged into the atmosphere.

The vacuum ladle is special equipment for sucking molten aluminum out of an electrolysis bath and transporting it to the casting workshop, and is required to adapt to the working environment of the electrolysis workshop and the casting workshop.

Regional Conditions:

Maximum magnetic field: 150GS

Composition of vacuum ladle

The vacuum ladle is composed of a ladle body, a ladle cover, a transmission mechanism, an aluminum suction pipe, a manhole device, an aluminum flowing port, an injector, a ladle hanger and so on.

Working Principle

The vacuum ladle carries out vacuum negative-pressure aluminum discharging under the working pressure of 0.5-0.6Mpa and ≥60kPa, and the injector is a crucial key part essential to generation of vacuum in the ladle and is shown in the figure 2. Compressed air conveyed from an air compressor of a crown block or an air compression station of the electrolysis workshop enters a jet nozzle, high-pressure air quickly passes through a spherical sleeve, and negative pressure (namely vacuum state) is generated at the periphery of the spherical sleeve to form an injection effect, so air in the ladle is injected into a silencer sleeve together with the compressed air through a flared pipe under the action of atmospheric pressure and discharged into the atmosphere.