The oil film bearing is widely applied to medium-plate mills, hot rolling mills, cold rolling mills and other various strip rolling mills, and is extremely

1. Works and classification:

Lubricating oil film bearing is a lubricating medium as radial bearings, works can be divided into hydrostatic bearings and hydrodynamic bearings.

⑴ hydrostatic bearing; hydrostatic bearing is to rely on static pressure lubricant formed around the rotor journal difference between external load work principle of equilibrium. Regardless of whether the axis of rotation, the journal is always floating in the pressure shaft, so that you can ensure that the work is in a state of pure liquid friction between the journal and the bearing. Therefore, these bearings have high rotational accuracy, strong friction characteristics of small carrying capacity, and on the speed of adaptation and vibration resistance is very good.

⑵ hydrodynamic bearing; hydrodynamic oil film bearing pressure is generated by the shaft itself, thus fueling system is simple, well-designed dynamic pressure bearing service life has always, therefore, a lot of rotating machines (eg expanders, compressors, pumps, motors, generators, etc.) are widely adopted hydrodynamic bearings.

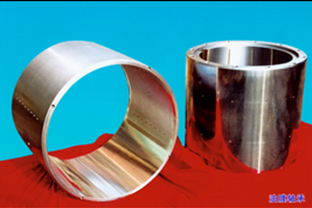

2, components:

⑴ bearing, consisting roll ⑵, ⑶ hydraulic nuts, ⑷DF seal, ⑸ bush, ⑹ sleeve, and other parts.

3, for the system range:

Mill Specifications (1200-4300)