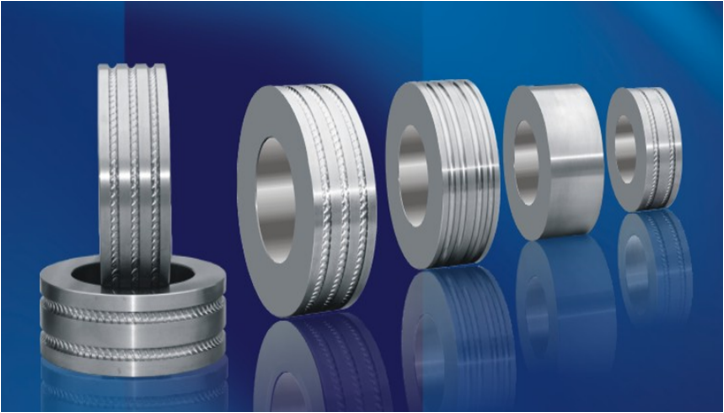

Cemented carbide rolls of various specifications ranged in two materials series of ZY and ZY-A in totally more than 20 grades are available in our company. The maximal outside diameter of our cemented carbide rolls can be reached to 500mm and the maximal thickness to 250mm. Specialized rolls are also available upon customers requests.

1) Roll ring dimension

Dimension range of finished roll rings

OD: 140-500mm

ID: 80-300mm

Height: 10-250mm

2) Product & Package

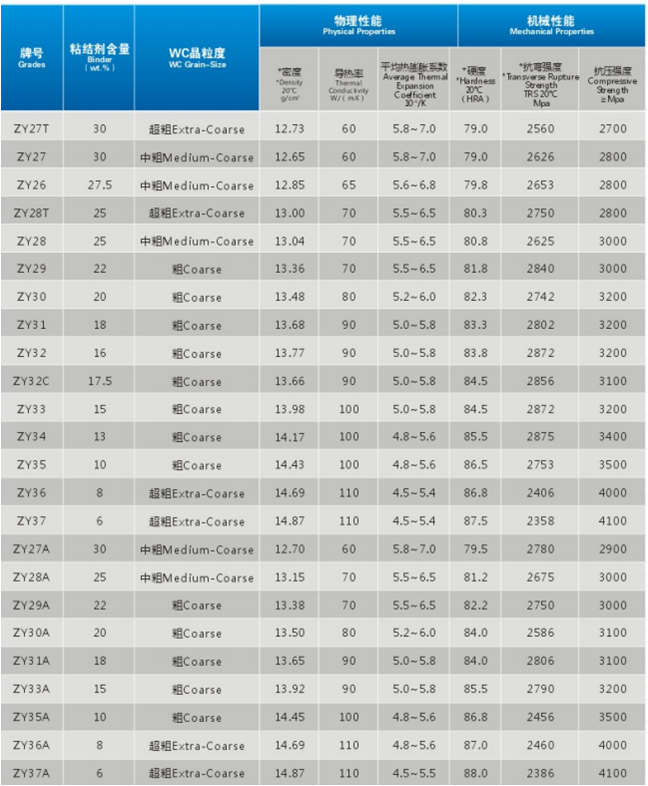

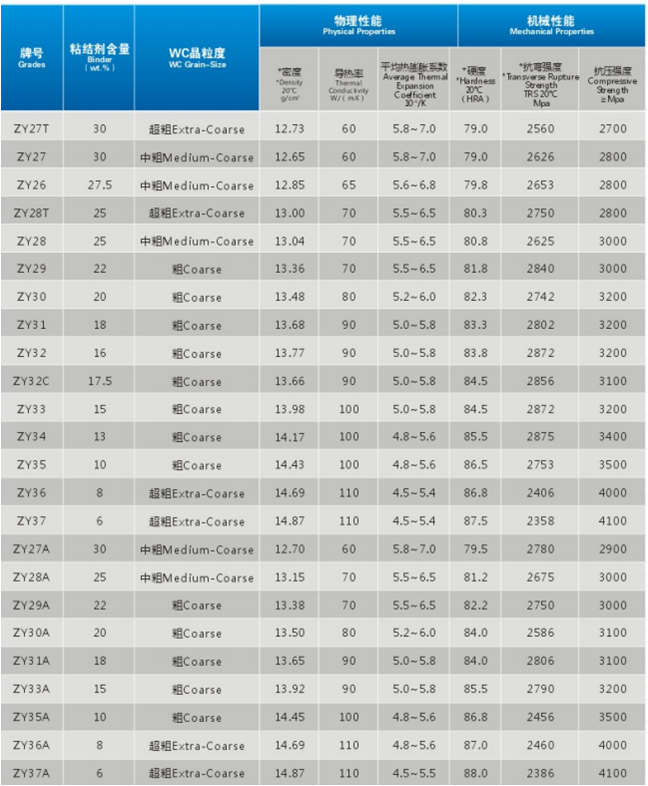

3) Grades and properties

The materials of ZY and ZY-A serials are able to satisfy customers' different requirements. The ZY serial grade contain acid corrosion-proof metal elements Ni and Cr in the binder, so that they are suitable for the cooling water of both that PH≥7.2 and PH<7.2.

According to customers' special requirements and actual working condition, we can offer ZY-A grades, and also develop the special grades for extra use. The grades of ZY-A serials have the properties of high hardness, good toughness and excellent thermal crack resistance, and are suitable for the use in the large force condition, but the cooling water should be alkaline with PH ≥7.2.

4) How to use

With high strength, high hardness, and good wear and thermal fatigue resistance , cemented carbide rolls(Composed of WC, Co, Ni and other rare metals) is developed for high-speed wire rolling. To make the best use of cemented carbide rolls, attentions should be paid to things listed bellow:

a) Selection of the grades

Choose the appropriate grades for different stands according to the work condition, such as rolling process, rolling speed and rolling loads.

b) Installation of roll-rings

Before installation, check the roll ring, tapered hosing, roller and clean the assembly surface of the ring, tapered hosing and roller.The match between roll ring, roller and tapered hosing should not be too tight or too loose. The same grade is suggested for the same stand.

c) Cooling of roll rings

Roll-rings must be cooled effectively to prevent thermal fatigue crack and to prolong the service life. 4-6 bar cooling water pressure is recommended for finishing stands, and a flow quantity of 250-300L//min per pass is required to ensure the surface temperature of the roll-rings surface less than 50℃.