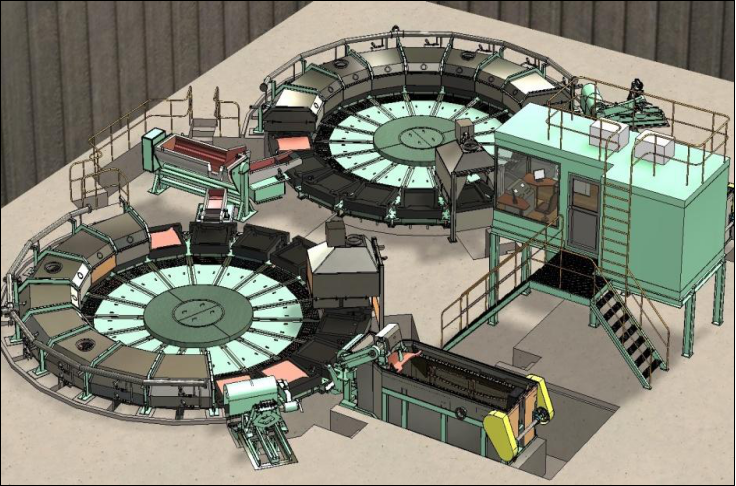

Liquid Copper came from the anode furnace,through a fixed chute,goes into the tundish, then through tilting mechanism to drive the tundish and pour into the copper ladle. With the help of weiging device on the ladle bottom, when the quantity of liquid copper meets the quota and mold rotates right at casting position, the control system will accurately make the ladle casting right amout of copper to the mold , ensuring same weight of each anode plate. After casting, tundish will dump the liquid copper again to ladle and wait for the next casting.

The mold with liquid copper will be cooled by spray cooling system, mold cooling by spray water from its bottom, anode plate cooling by spray water from its top. Solenoid valve is used to regulate the total amount of water spray cooling, manual valve is used to control the amount of water for each mold.

After cooling, the anode plate separate from mold by pre-jacking device. Duing pre-jacking, the hydraulic locking device will lock mold tightly, in order to avoid deformation of the disc component. When there is a casting defect or a deformation beyond standard scope happened on one anode plate, this anode plate is determined to be disqualified, the take-off device will take the anode plate out.

When the mold rotates to the take off position, the anode plate will be jacked again ,then being taked off and put into water trough. In the trough, the chain conveyor will transfer anode plate to the other side of trough, where there is lifting device to raise anode plate to specified height, then the anode plate will be delivered by folklift.

After the anode plate take off, the empty mold will rotate to spray painting position, barium sulfate or similar coating materials will be sprayed on for next casting and mold releasing.

After cooling, the anode plate separate from mold by pre-jacking device. Duing pre-jacking, the hydraulic locking device will lock mold tightly, in order to avoid deformation of the disc component. When there is a casting defect or a deformation beyond standard scope happened on one anode plate, this anode plate is determined to be disqualified, the take-off device will take the anode plate out.

When the mold rotates to the take off position, the anode plate will be jacked again ,then being taked off and put into water trough. In the trough, the chain conveyor will transfer anode plate to the other side of trough, where there is lifting device to raise anode plate to specified height, then the anode plate will be delivered by folklift.

After the anode plate take off, the empty mold will rotate to spray painting position, barium sulfate or similar coating materials will be sprayed on for next casting and mold releasing.

2.Equipment capacity

Big plate double-disc Big plate single-disc Small plate double-disc Small plate single-disc

Casting ability 80-110 t/h 40--55 t/h 50-70 t/h 25--35 t/h

Anodes weight 345-430 kg 345--430 kg 220-285kg 220-285kg

Casting mode Auto weighing Auto weighing Auto weighing Auto weighing

Weight error less than ±1% less than ±1% less than±1% less than ±1%

Percent of pass greater than 98% greater than 98% greater than 98% greater than 98%